Developing your own analysis program

An oil analysis program is much more than just a technical tool for condition monitoring and maintenance. Creating a well-designed program means building a clear, scalable, step-by-step system that delivers real, measurable benefits: better foresight, reduced risks, and smoother operations.

Are you squeezing the full value out of your current oil analysis program — or is it time to optimize it and unlock the full benefits of doing it right?

Why analyse oils?

As a business leader, your job is to keep operations running, avoid accidents, and make smart, profitable decisions. But too often, problems build up quietly and risks go unnoticed — until it’s too late. Machines break down, costs go up, and customer trust suffers. On top of that, valuable resources are wasted, and the environment is negatively impacted.

That’s where oil analysis and proactive maintenance come in. Together, they offer a simple yet powerful way to spot issues early — before they spiral out of control. But here’s the key:

“What doesn’t get measured, can’t be improved.”

This is more than just a saying — it’s a proven way to gain a competitive edge. Companies that monitor, measure, and act don’t just avoid problems — they run smarter, save money, and stay ahead of others.

Traditionally: Oil analysis as a maintenance tool

Traditionally, oil analysis has been used primarily as a maintenance tool — a quick and cost-effective method for checking machine condition and oil quality. And it still serves that role extremely well.

Clean oil with the right properties protects your equipment and can significantly extend the life of both lubricants and mechanical components — in some cases, by a factor of ten or more.

Regular analysis helps you identify early signs of trouble: weakening lubrication, increased wear, or declining filtration performance. In short, it tells you when it’s time to act — before minor issues turn into major problems.

A well-implemented oil analysis setup gives you peace of mind. It supports smarter maintenance planning, minimizes unplanned downtime, and keeps operations running smoothly.

Today: Oil analysis as a strategic tool

Today, oil analysis has grown beyond being just a maintenance tool. It now supports company-wide goals — risk management, quality assurance, and continuous improvement. When used effectively, the data from oil analysis strengthens your management systems, supporting everything from achieving quality and environmental targets to increasing workplace safety.

Benefits from different perspectives

- Quality: More reliable machines and increased product quality.

- Environment: Longer-lasting lubricants reduce both waste and consumption.

- Safety: Spot anomalies before they become hazards — critical for equipment like cranes or aircrafts.

- Employee Health: Monitoring harmful substances such as heavy metals or PCBs safeguards your team.

Department-specific benefits

How to build a smart oil analysis program

A successful oil analysis program doesn’t happen by accident. It’s intentional, structured, and built into everyday operations. Here’s a practical step-by-step guide to help you get started:

1. Start with a purpose — Improve efficiency, reduce costs, ensure safety, and/or support quality.

2. Choose the right machines — Focus on systems based on importance/criticality, component types, failure history, and strategic goals.

3. Plan your sampling — Define the frequency, tools, and techniques.

4. Train your samplers — Emphasize safety, accuracy, and error prevention.

5. Collect background info — Include machine specs, oil type, filter types, oil volumes, etc.

6. Pick the right lab — One that aligns with your needs and expectations.

7. Customize your analysis packages — Tailored to your equipment and operations.

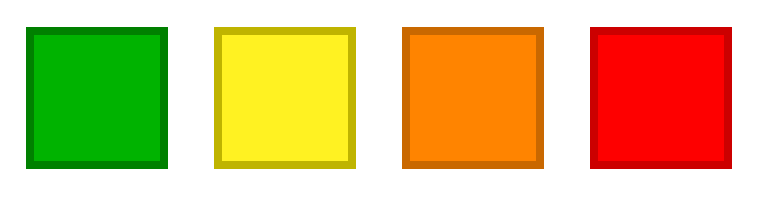

8. Set alarm/warning limits — Define thresholds per system or component.

9. Decide on report format — Paper, PDF, online portal, or ERP-integrated.

10. Send samples to the lab.

11. Review results in full — See diagnostics, trends, and predictions.

12. Assign responsibilities — Clarify who follows up and what happens next.

13. Take action — And keep track of outcomes.

14. Keep improving — Train staff, tweak analysis content, and stay up to date.

Summary

Oil analysis isn’t just a technical routine — it’s a powerful business tool. It gives you deeper insight into your machines, your processes, and the risks that could disrupt them.

When you act based on real data, you unlock smarter decisions, more efficient operations, and long-term improvements. Companies that monitor oil condition and respond strategically don’t just cut costs — they boost reliability, strengthen their market position and build a more resilient, sustainable future.

Measure. Understand. Improve. Grow.

This isn’t just about maintenance. It’s about being smarter than yesterday — and ready for tomorrow.

Ready to create your own analysis program?

We’ve helped numerous leading companies develop theirs — now let’s make one for you too!